What is Megasoft?

Megasoft, developed by Megatech Business Solutions, is a versatile software solution that seamlessly collects, manages, and processes data in SYSPRO ERP.

It's compatible with both desktop and mobile devices, including smart mobile scanners, making it a device-agnostics solution. The user friendly interface facilitates precise data collection, and data processing occurs within Syspro via Syspro Business Objects, ensuring compliance with all the business rules defined in your ERP system.

Megasoft System Features

Procurement

Centralized procurement with DOA email approval

Authorization Limit based on Ledger codes

Supplier quotes attached to requisitions

Req Audit trail

Maintenance

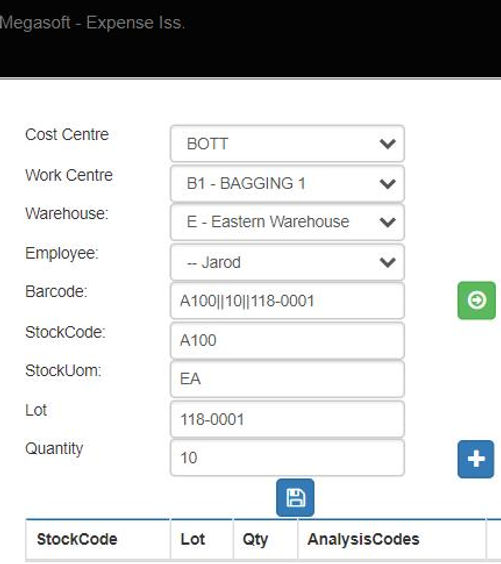

Maintenance part scan and expense issues via ledger code matrix

Sales

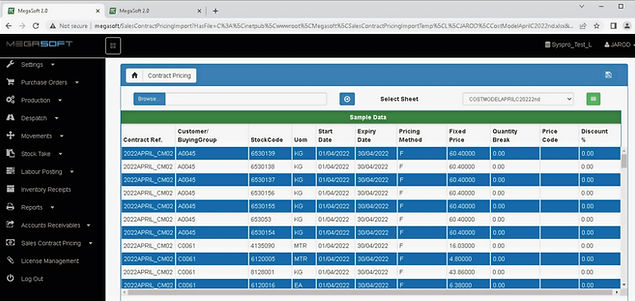

Customer contract price posting

EDI for Invoices to Customer Portals

Warehouse Management

Goods scanned and binned in Warehouse.

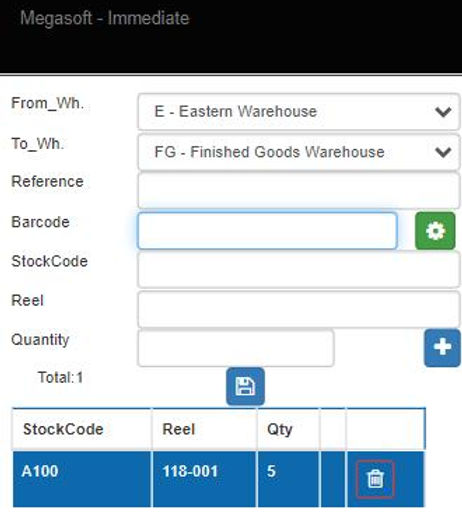

Scanning of boxes or pallets and transferring goods between warehouse and bins.

Picking of goods for dispatch using scanners.

Picking based on picker types and bin types.

Checking of items to ensure accuracy.

Invoicing or dispatching in Megasoft with real

time posting to Syspro.

Stock take scanning and cycle counts.

Receiving of Goods

Goods received are labelled and scanned.

GRN posted directly to Syspro with GRN number returned to user.

Goods can then be scanned and transferred to required warehouse or bins

Production

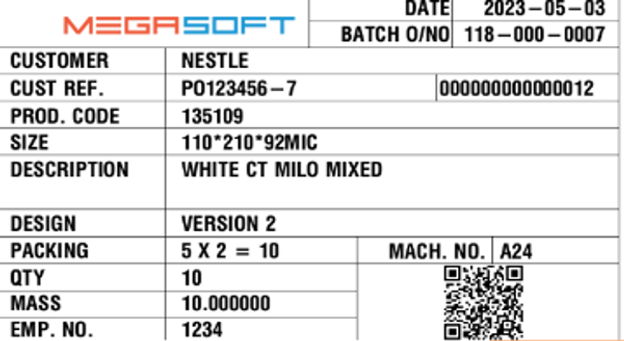

Barcode labelling of Finished Goods and Semi-Finished Goods.

Scale integration for weighing of goods. Improves accuracy of data processed.

Material Issues to Jobs via scanning.

Jobs receipts processed efficiently via scanning and scaling.

Box and pallet tracking or goods produced.

Production summary and detail reporting.

Labour posting and scrap posting with one easy to use interface.

Drag and drop Factory Scheduler